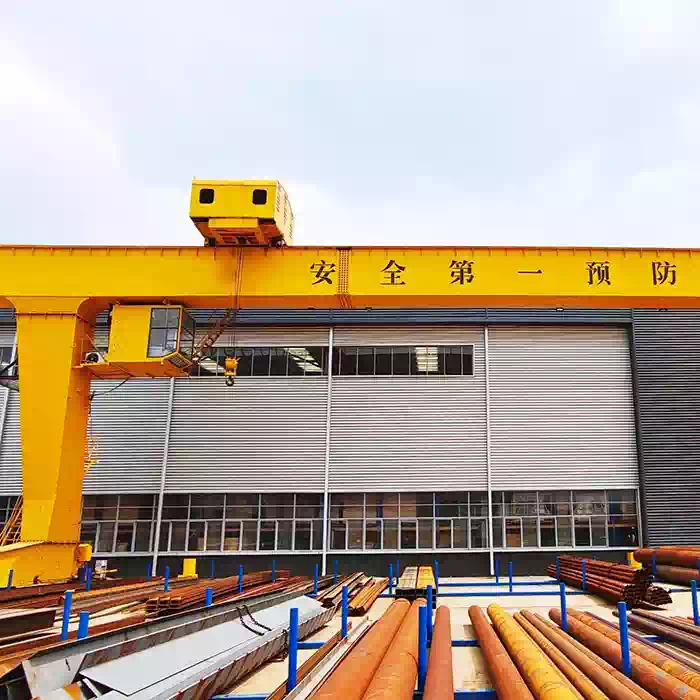

The segmented leg gantry crane is highly suitable for use in situations where large cranes cannot enter. In construction sites within urban areas, for instance, the presence of narrow, winding streets and tight spaces between existing buildings often restricts the entry of large - scale, bulky cranes. Here, the segmented leg gantry crane's design proves invaluable. Its legs, divided into multiple sections, can be easily transported through these constricted passages. Once on - site, the sections are assembled piece by piece, a process made feasible due to their manageable size.

Industrial plants undergoing renovation also frequently encounter such scenarios. Existing machinery and equipment, along with complex piping systems, can clutter the area, leaving no room for large cranes to maneuver. The segmented leg gantry crane, with its modular leg design, can be set up in a step - by - step manner. Each leg section, equipped with a jack - up support, allows for precise elevation and alignment during installation. This adaptability ensures that the crane can be operational even in the most challenging of spaces.

In remote locations where the terrain is uneven or there are no proper access roads, large all - terrain cranes might still struggle to reach the work area. The segmented leg gantry crane, however, can be disassembled into smaller segments for transportation. These segments can be carried by smaller vehicles or even manually in some cases. Once at the site, the crane is reassembled, with the leg sections being joined using flanges to form a stable structure. This enables it to perform essential lifting tasks such as moving construction materials for building small - scale power plants or installing equipment in mining operations that are located in hard - to - reach areas.